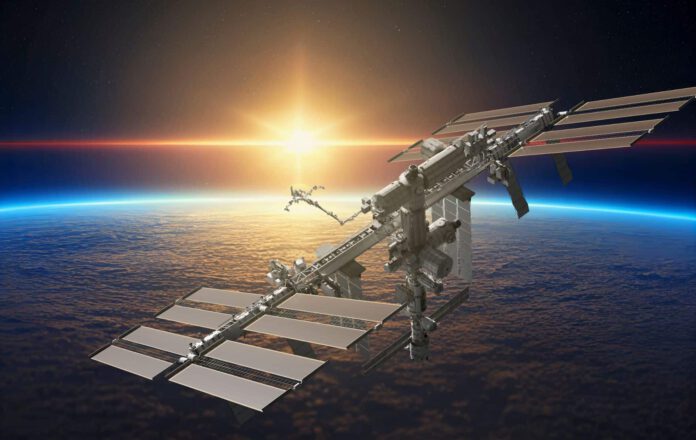

3D Metal Printing Taking Place in Space

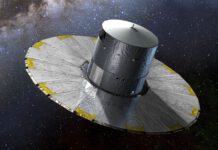

The concept of 3D printing with metal already sizzles with excitement, but the European Space Agency (ESA) has taken it up a notch – they’re doing it in space. Last Wednesday, a special 3D printer embarked on a resupply mission to the International Space Station (ISS).

One might ponder, why having a metal 3D printer on board the ISS? The goal is to foster a circular space economy in the future, reusing materials circulating around the Earth. This printer can repurpose parts of old satellites into tools or metal plates for the space station. This eliminates the need for launching rockets from Earth just to transport required materials.

A Space Milestone

This is the first-ever space outing for a 3D printer capable of creating metal objects. Earlier, a standard 3D printer -capable of printing plastic materials- had been used on the ISS. “Printing metal is a significant technical challenge, requiring much higher temperatures and melting the metal with a laser, presenting potential hazards to the safety of the crew and the space station itself. Maintaining the printer is also quite limited. However, once achieved, the strength, conductivity, and stiffness of the metal will raise the potential of 3D printing in space to new heights”, pointed out ESA engineer, Rob Postema.

Airbus’ Innovation

The 3D printer, weighing approximately 180 kg, was developed by a team at Airbus. Once installed, the printer is remotely operated from Earth, freeing the astronauts in the ISS to focus on other tasks. “This isn’t merely a step towards the future, it’s a leap for innovation in space, paving the path for more complex metal constructions in space. This is pivotal for the exploration of the moon and mars”, explained Patrick Crescence, project manager at Airbus.

A Stainless Steel Printer

The printer prints a specific type of stainless steel commonly used in medical implants and water purification, given its high resistance to corrosion. A stainless steel wire is fed to the printer, which is heated by a powerful laser -a million times stronger than the average laser pen. The wire tip melts and is added to the print as metal.

Metal Printing on Earth

“The melting point of stainless steel is around 1400 degrees, therefore, the printer is in a completely sealed box to keep the heat and smoke from reaching the ISS astronauts. Before the printing process begins, the oxygen inside the printer must be expelled into space and replaced with nitrogen. The hot steel would oxidize if exposed to oxygen”, explains ESA engineer, Advenit Makaya.

Testing Phase

Don’t anticipate entire components and tools rolling out yet, everything is still in the testing phase. Four print shapes have been selected for this purpose, which will be compared with the same shapes that are printed on Earth to examine the effect of space on the printing process. All four shapes are smaller than a soda can and weigh less than 250 grams each. Printing them takes two to four weeks, but, to minimize noise, the machine only prints for four hours each day.

When one is finished, it is sent back to Earth for further investigation. “Our aim is to prove the potential of 3D printing with metal in space”, says Postema. “We want to learn much more about the possibilities of this process, to ultimately make the production of parts in space an everyday practice”.

Colonising Mars

If we ever establish colonies on Mars, this technology will be indispensable. “3D metal printing is a promising technique to support future space exploration and contribute to more sustainable space activities through manufacturing, repair, and perhaps recycling of space structures. This applies not only to large infrastructure orbiting Earth but also to long-term human settlements on other planets”, concludes Tommaso Ghidini, head of the mechanical department at ESA.